scroll down for a customer success story ˅

Features:

- Automatic blade measurement

- Constant load monitoring

- Constant pressure monitoring

- Constant surface speed

- No material deformation

- Increased tool life

- Better yield loss

- Less cost per ton

Options:

- Hot and Cold material cutting

- Single or batch cutting

- Swarf Collection Systems

- Dust Collection Systems

- Material measuring

- Rotating Modules for cutting large diameter materials

- Complete material handling systems

SPECIFICATIONS

Bar Section

Up to 16 inches single cut (400mm)

Wheel Diameter

Up to 60 inches (1524mm)

Surface Speed of Wheel Up to 24,000 SFPM (73m square/second)

Cutting Speed (average, depending on material)

Up to 3.0 inches square/second (19cm square/second)

Feed Rate Control

Adaptive servo controlled with closed loop feedback

Cutting Temperature

Ambient to 1800 degrees F (ambient to 1000 degrees C)

Motor Power (with automatic RPM regulation)

Up to 400 HP/ A/C VF (224KW)

Sequence Control

PLC (Programmable Logic Controller)

Saw Blade Speed Control

With automatic wheel-diameter-measuring;

speed up control by PLC and A/C VF motor drive

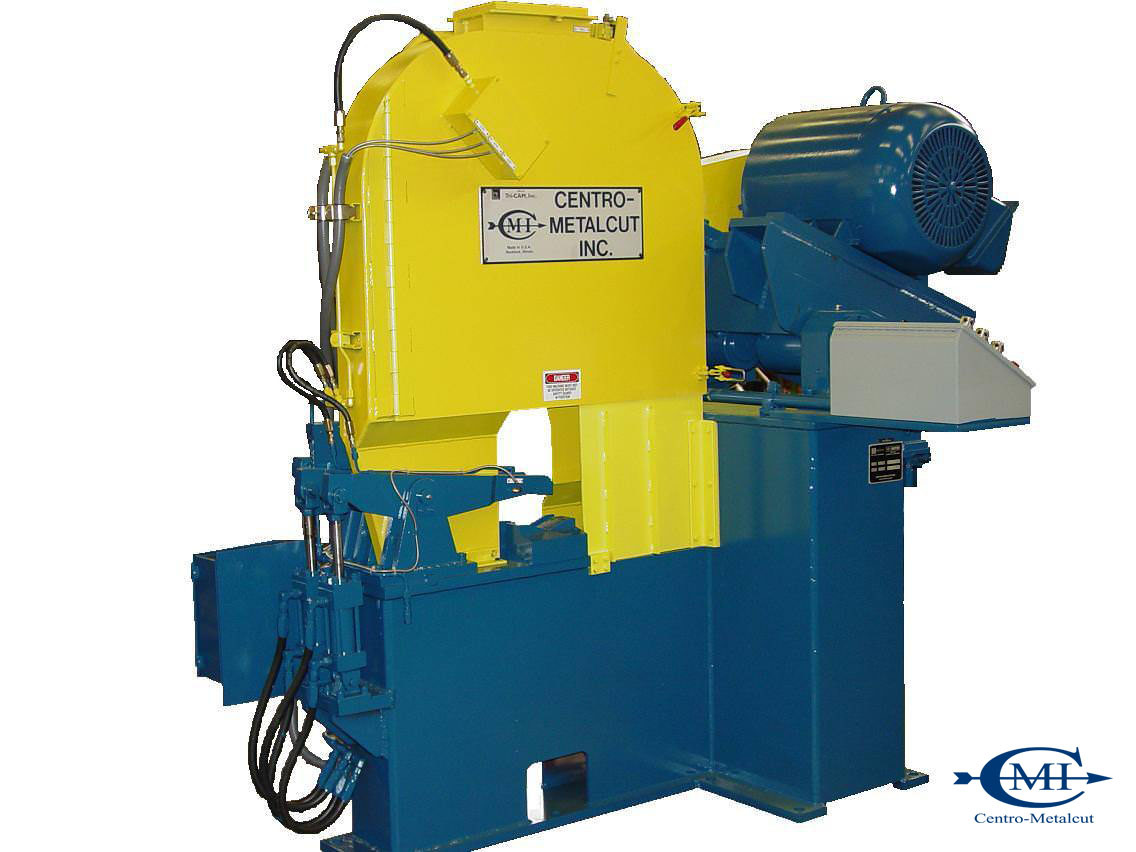

COMPANY Houston, TXThe company produces close-die, high integrity forgings for the aerospace and energy markets. |

EQUIPMENT CAH 1220 Saw150HP, 48” abrasive wheel, material temperatures up to 2100°F. |

FEATURES Portable MachineDesigned to be portable so it could be easily moved from one production line to the next. |

APPLICATION

Benefits

The customer was producing forged bars and needed a fast, efficient way to cut the material to various lengths. The saw went into an existing facility that had multiple finishing lines. The customer needed flexibility to move the saw between lines based on their customer material requirements. Abrasive saws provide a fast, efficient means of cutting high alloy materials. Compared to band saws; abrasive saws can be over 400% faster, which means a quicker ROI. This was the first of two custom saws that we supplied to this facility. The customer chose CMI as we were willing to design and manufacture a custom-tailored solution to meet their requirements.