Features:

- Superior finishes

- Controlled removal

- Constant surface speed

- Grind any steel material grades

- Automatic grinding head pressure control

- Heavy duty pivot bearings for durability and longevity

Options:

- Hot or cold grinding

- Billets, blooms, rounds

- Small or large slabs

- Wireless controllers

- Swarf and dust collection systems with wireless travel synchronization

- Material handling equipment - turning tables, support stands, rotating tables

SPECIFICATIONS

Main Motor

Up to 75hp

Grinding Wheel

24" diameter x 3" wide

Grinding Wheel Speed

Up to 16,500 SFPM

COMPANY New Castle, PAThe company produces Forged High Alloys products for the aerospace, automotive, defense, industrial, marine, mining & construction, oil & gas, power generation, transportation & infrastructure, and tooling industries. |

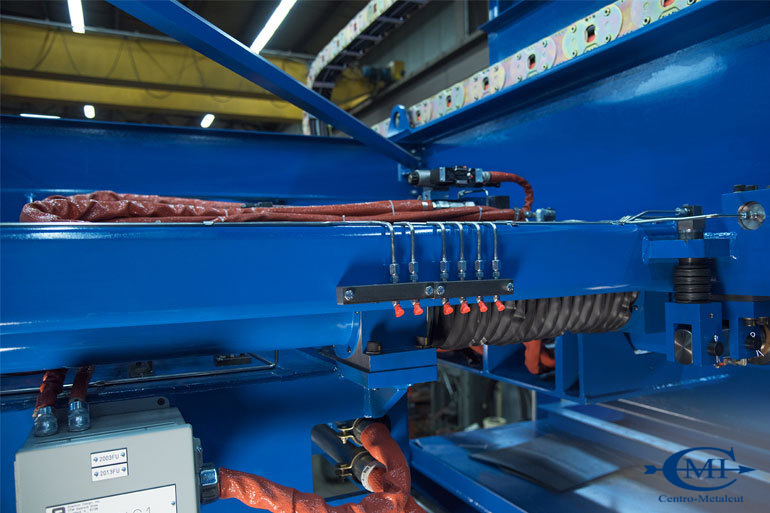

EQUIPMENT OH450/75HPGrinds Alloy ingots from 10”–31” diameter x 174”–197” long. 75HP with a 24” x 3” grinding wheel. Travel lengths of 50’. |

FEATURES WirelessWireless remote operation (new feature), 75HP grinding motor (larger than others). |

APPLICATION

Benefits

The customer is doing finish grinding on ingots before shipping to their customer. The customer previously used a swing grinder which is VERY labor intensive and put the operator within inches of the grinding wheel. This became a growing safety concern. They wanted an operator-friendly machine that was not labor-intensive and much safer operation. Must safer design compared to a swing grinder, superior wireless control capability. The customer has been very complimentary of the machine’s functionality, safety and its reliability.